DTF (Direct-to-Fabric) Printing is a modern fabric design method using specialized printers to apply inks directly onto fabrics, eliminating intermediate materials and streamlining production. High-quality designs are created or acquired and printed onto transparent film for optimal color. The film is then positioned over fabric and exposed to light, creating a reverse imprint. After removing the film, the fabric is cured with heat or UV light to permanently fix the inks. DTF Printing offers versatility, durability, and vibrant results on diverse fabrics, suitable for small batches or on-demand custom designs. Proper fabric selection, preparation, and equipment maintenance are crucial for achieving superior printing quality. This innovative technique has revolutionized fabric design, empowering creators to bring unique visions to life with intricate, personalized patterns accessible in various applications.

Discover the innovative world of DTF Printing—a cutting-edge technique transforming fabric design. This modern method allows for precise transfer of intricate designs directly onto fabrics, opening doors to endless creative possibilities. From understanding the core process to selecting optimal materials, this guide explores every aspect of DTF Printing. Learn about different film types, fabric choices, and expert tips to achieve stunning results. Unleash your creativity with this versatile and unique approach to fabric design.

- Understanding DTF Printing: A Modern Fabric Design Technique

- The Process: From Film to Fabrics Step-by-Step

- Types of Films and Their Applications in DTF Printing

- Choosing the Right Fabric for Optimal Print Results

- Tips and Tricks for Achieving High-Quality Prints

- Creative Possibilities: Unique Designs and Customization

Understanding DTF Printing: A Modern Fabric Design Technique

DTF (Direct-to-Fabric) Printing is a cutting-edge technique revolutionizing the way we transfer designs onto fabrics. Unlike traditional methods, DTF offers a direct and efficient approach, enabling designers to create vibrant, high-quality prints on various fabric surfaces. This modern method involves using specialized printers that apply inks directly to the fabric, ensuring precise color reproduction and intricate detail retention.

By eliminating the need for intermediate materials like film or paper, DTF Printing streamlines the production process. Designers can easily preview and adjust designs before printing, making it an versatile option for both small-batch production and on-demand custom fabrics. The direct application of ink also allows for a more robust and long-lasting finish, ideal for outdoor applications or high-traffic areas, ensuring that designs remain vibrant and clear even under demanding conditions.

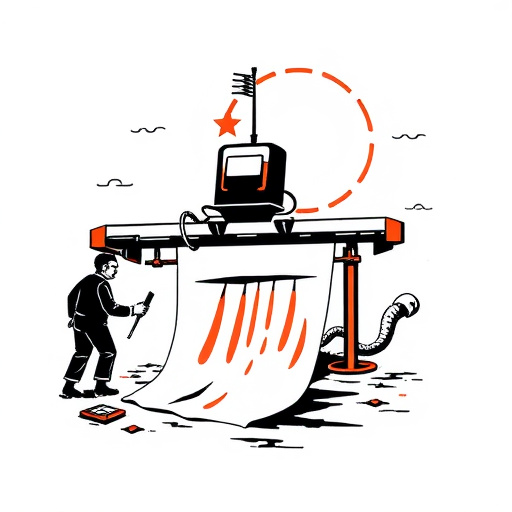

The Process: From Film to Fabrics Step-by-Step

The process of transferring designs from film to fabrics via DTF (Direct to Fabric) Printing is a multi-step technique that involves several precise actions. It begins with the creation or acquisition of a high-quality design file, which can be created using graphic design software or sourced from external designers. This digital artwork is then printed onto transparent film, ensuring the correct color profiles and resolution for optimal results.

Next, the film is positioned over the fabric, with the design facing down, allowing light to pass through. A specialized machine then exposes the fabric to the printed film, hardening the areas that are in contact with the design. After exposure, the film is carefully removed, leaving a reverse imprint of the design onto the fabric. The final step involves curing the printed fabric using heat or UV light to ensure the inks adhere permanently to the material.

Types of Films and Their Applications in DTF Printing

In the realm of DTF Printing, various types of films play a pivotal role in achieving intricate and vibrant designs on fabrics. These films act as versatile mediums, enabling printers to transfer patterns with precision and quality. One commonly used film is the transfer paper, which is ideal for light-colored fabrics. It allows for easy application of designs by simply ironing or heat pressing the paper onto the fabric, making it a popular choice for home enthusiasts and small businesses.

Another significant type is mylar film, known for its durability and versatility. This film is suitable for both light and dark fabrics and can handle more complex designs with finer details. Mylar’s ability to withstand higher temperatures opens up possibilities for more permanent and robust transfers, making it a favorite among professional printers. Its flexibility allows for easy wrapping around curves and edges, ensuring that every part of the design is precisely applied to the fabric.

Choosing the Right Fabric for Optimal Print Results

When it comes to DTF (Direct to Fabric) printing, selecting the appropriate fabric is key to achieving exceptional print results. Different fabrics have unique properties that can impact the final outcome, so understanding their characteristics is essential for printers and designers alike. The texture, absorbency, and composition of the fabric play significant roles in how well the design transfers and the overall quality of the printed item.

For instance, natural fibers like cotton and linen are popular choices due to their ability to absorb ink effectively, resulting in vibrant and detailed prints. Synthetic fabrics, such as polyester or nylon, offer advantages like fast drying times and increased durability but may require specific setting techniques to ensure the print adheres properly. Pre-treating or preparing the fabric according to the material type is crucial to achieving optimal DTF printing success.

Tips and Tricks for Achieving High-Quality Prints

When it comes to achieving high-quality prints using DTF (Direct to Fabric) printing techniques, preparation is key. Start by ensuring your fabric is clean and free from any dirt or debris to prevent imperfections on the final design. Pre-treating the fabric with a suitable spray can help improve ink adhesion and create a smoother surface for printing. Choose high-quality print files with sharp images and accurate color profiles to guarantee the best results.

For optimal DTF Printing, consider using specialized printers designed for textile applications, as they offer precise control over settings like temperature and pressure. Calibrate your printer regularly to maintain consistent performance. Experiment with different ink types and settings to find the perfect combination for your fabric choice, ensuring vibrant colors and crisp details. Regularly cleaning and maintaining your printing equipment is also vital to maintain print quality over time.

Creative Possibilities: Unique Designs and Customization

The world of fabric design has been transformed by Digital Transfer Film (DTF) Printing, unlocking a realm of creative possibilities. This innovative technique allows designers and enthusiasts alike to bring unique and intricate patterns to life on various fabrics with ease. One of its standout features is the ability to create custom designs tailored to individual preferences. Whether it’s a fashion designer sketching out a seasonal collection or an artist looking to print their original artwork onto fabric, DTF Printing offers a versatile platform for self-expression.

With this method, the sky’s the limit in terms of design complexity and customization. Designers can seamlessly incorporate detailed illustrations, bold graphics, and even photographic images directly onto fabrics. The process enables quick iterations, allowing creators to experiment with different styles and concepts without the traditional time constraints. This level of customization has revolutionized the way we approach fashion, home decor, and art, fostering a culture where one-of-a-kind, personalized creations are easily accessible.