DTF Transfer Printing (Direct-to-Fabric) is a modern method for creating vivid, high-quality designs on various fabrics and materials like apparel, signs, and home decor. It involves transferring ink directly from a print head to fabric using specialized equipment and techniques. Success requires specific gear, including a compatible printer, DTF ink, and appropriate printing media like heat-press machines. Ignoring these essentials can result in subpar prints. DTF printing's versatility, ease of use, and vibrant results make it ideal for artists and businesses creating custom designs for apparel or promotional items in today's market.

Choosing the right equipment is paramount for a successful DTF transfer printing setup. This article guides you through the essential components needed to master the Direct to Film (DTF) printing process, enhancing precision and efficiency. From understanding the fundamentals of DTF, including its advantages and applications, to identifying crucial equipment like film/plotter, inkjet printers, and optional cutting machines, this comprehensive guide covers all bases. Explore additional tools, accessories, and software solutions that promise enhanced productivity and optimal results in your DTF transfer printing journey.

- Understanding DTF Transfer Printing and Its Requirements

- – Definition and process overview

- – Advantages and applications of DTF (Direct to Film) transfer printing

Understanding DTF Transfer Printing and Its Requirements

DTF (Direct to Fabric) Transfer Printing is a direct printing method that allows for high-quality reproduction of vibrant designs onto various fabrics. This process involves transferring ink from a print head directly onto the fabric, creating detailed and precise images. Understanding DTF’s unique requirements is key when setting up your printing setup. The technology demands specific equipment and materials to ensure optimal results; ignoring these needs could lead to subpar prints on dtf printed shirts or custom dtf gang sheets.

A successful DTF transfer print relies on a few critical factors. First, you’ll need a compatible printer designed for direct-to-fabric printing. These printers typically offer high resolution and precision, ensuring intricate details are captured accurately. Additionally, specialized ink formulated for DTF printing is essential; it should be able to adhere strongly to the fabric while still allowing for a smooth transfer process. The right printing medium, such as heat-press machines or drying cabinets, plays a significant role in achieving crisp and long-lasting prints on custom dtf gang sheets.

– Definition and process overview

DTF Transfer Printing, or Direct-to-Garment (DTG) printing, is a cutting-edge technique that allows for the creation of vibrant designs on various materials, particularly custom apparel. This process involves transferring ink directly onto the garment using specialized equipment and techniques. The journey begins with designing or sourcing artwork, which is then prepared for printing. Once ready, the dtf transfers are placed onto the desired garment, usually a t-shirt or hoodie, and pressed using a heat press machine. Heat activates the ink, fusing it permanently onto the fabric, resulting in high-quality, long-lasting prints. This method offers immense versatility, enabling creators to produce unique, custom apparel with intricate and detailed designs.

Whether you’re an entrepreneur looking to launch a custom apparel line or an artist seeking to showcase your creations, DTF Transfer Printing is a game-changer. With readily available dtf transfers and user-friendly equipment, the process empowers individuals to turn their imaginative designs into tangible products swiftly. The end result? Stunning, vibrant designs that leave a lasting impression, ensuring your garments stand out in a sea of ordinary.

– Advantages and applications of DTF (Direct to Film) transfer printing

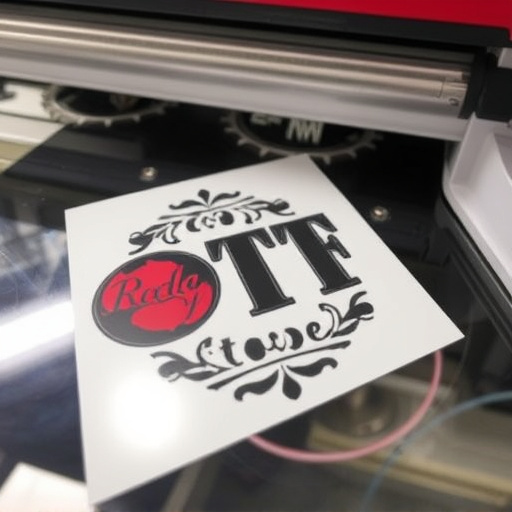

Direct to Film (DTF) transfer printing is a game-changer for businesses and enthusiasts looking to create high-quality custom designs on various materials, from textiles to ceramics. This cutting-edge technique offers several advantages over traditional printing methods. With DTF, you can achieve vibrant colors, sharp details, and precise line work directly onto the film, eliminating the need for expensive plates or screens. This makes it an efficient and cost-effective solution for small to bulk orders, catering to both individual artists and commercial enterprises.

DTF printing’s versatility is another standout feature. It enables printers to produce complex artwork with ease, making it ideal for promotional items, apparel, signs, and even custom home decor. The ability to quickly adapt designs and offer unique, personalized products sets DTF transfer printing apart in today’s competitive market. Whether you’re looking to create limited-edition collectibles or cater to diverse customer preferences, DTF offers a versatile and accessible platform for bringing your creative visions to life.

When setting up a DTF Transfer Printing equipment, understanding the process and its unique requirements is key. DTF offers precise, vibrant results with a wide range of applications, from custom apparel to promotional items. By selecting high-quality printers, inks, and films suitable for your intended use, you can achieve exceptional outcomes. Remember that investment in top-tier materials and proper training will ensure a successful and rewarding DTF Transfer Printing journey.