DTF Transfer Printing is a modern high-volume production method for apparel, offering swift and precise design transfers onto various fabrics via heated press and specialized paper. It ensures vibrant colors and accurate design placement, ideal for custom t-shirts. This technology surpasses traditional methods in efficiency, allowing brands to achieve exceptional customization while maintaining cost-effectiveness across diverse printing surfaces. Strategic planning, proper equipment use, and adherence to best practices are crucial for successful implementation.

“Discover the game-changing potential of DTF (Direct to Fabric) Transfer Printing for high-volume production. This cutting-edge technology is revolutionizing manufacturing, offering unparalleled efficiency and quality in fabric printing. From understanding its unique process to exploring the myriad benefits and implementation strategies, this article guides you through the key aspects of DTF Transfer Printing. Uncover how it enhances productivity, reduces costs, and opens doors for diverse applications.”

- Understanding DTF Transfer Printing Technology

- Benefits for High-Volume Production Runs

- Implementation and Best Practices for Success

Understanding DTF Transfer Printing Technology

DTF Transfer Printing is a cutting-edge technology that has revolutionized high-volume production runs, especially in the apparel industry. This process involves transferring ink from a printing plate or screen to a substrate, typically fabric, using a heated press and a thin layer of transfer paper. It’s a versatile method that allows for intricate designs and detailed graphics on various materials, making it ideal for DTF printing for t-shirts and other light fabrics.

The technology offers several advantages. First, it enables fast production times without compromising quality, ensuring efficient DTF for apparel. Second, it’s suitable for a wide range of fabric types, including cotton, polyester, and nylon, making it a go-to choice for many clothing manufacturers. Additionally, DTF Transfer Printing provides vibrant color reproduction and accurate design placement, resulting in high-quality finished products. This method has truly transformed the way apparel is produced, offering both speed and precision in equal measure.

Benefits for High-Volume Production Runs

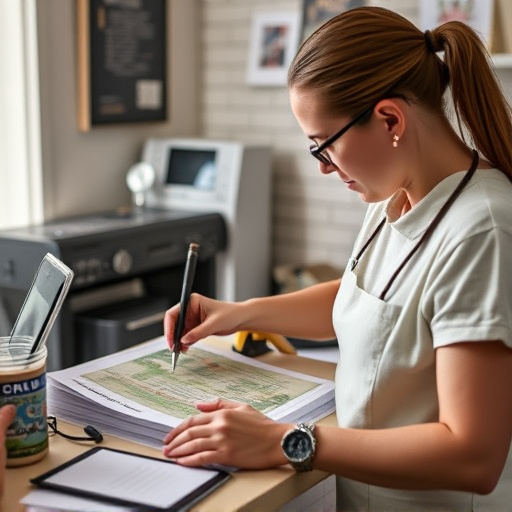

For businesses engaging in high-volume production runs, especially for custom t shirts and other garments, DTF Transfer Printing offers significant advantages. This technology streamlines the process by enabling precise and detailed designs to be effortlessly transferred to a wide array of materials. Unlike traditional methods that can be labor-intensive and time-consuming, DTF printers facilitate efficient batch processing, ensuring consistent quality across every print.

With custom DTF transfers, brands can achieve exceptional levels of customization and flexibility. Whether it’s intricate graphics or vibrant colors, DTF Transfer Printing allows for precise color replication and fine detail preservation. This makes it ideal for creating unique, on-demand products while maintaining operational cost-effectiveness. The versatility of this method extends beyond textiles, opening doors to printing on various surfaces, from ceramics to wooden items.

Implementation and Best Practices for Success

Implementing DTF Transfer Printing for high-volume production runs requires a strategic approach and adherence to best practices to ensure success. Firstly, selecting the right equipment is pivotal; invest in reliable DTF printers capable of handling your projected output. The choice of ink, paper, and press settings must be tailored to the specific fabric type, ensuring optimal dtf prints each time. For light fabrics, specialized transfer papers designed for enhanced adhesion are essential.

Training staff on the intricacies of dtf printing for light fabrics using a heat press is crucial. This includes understanding material limitations, press temperature controls, and drying times to prevent smudging or bleeding. Standardizing processes creates consistency in your production runs, allowing for efficient quality control measures. Regularly maintain equipment and perform tests to guarantee accuracy and precision across every print job.

DTF Transfer Printing offers a game-changing solution for high-volume production runs, streamlining processes and enhancing efficiency. By understanding this technology and implementing best practices, businesses can achieve remarkable results in printing quality, speed, and cost-effectiveness. Embrace the future of manufacturing with DTF Transfer Printing as a reliable and innovative method to meet your production demands.